What Are You Looking For?

What Are You Looking For?

Good insulation performance: SF6 gas insulation is used, which has strong insulation performance.

Five-protection interlocking: High-reliability interlocking device realizes the "five-protection" locking function to meet safety needs.

Save investment: small size, small footprint, saving capital investment costs.

Modular design: Modular assembly structure, can be combined and expanded with different functional units according to customer needs.

Intelligent monitoring: Provides an intelligent power distribution system with supporting protection, remote control, monitoring, intelligent fault handling and other functions, and integrated debugging in the factory.

Three-remote design: The operating mechanism can be manual and electric, which is convenient for realizing the "three-remote" requirements of the power system.

Item NO. :

RM6-12/24Lead time :

35 DaysPayment :

T/TMOQ :

≥1Warranty :

1 Years(SF6) Unit Type AC Metal-Enclosed Ring Main Unit

Enecell is Professional China SF6 Gas Insulated RMU Manufacturers, HXGN-12 box-type fixed AC metal-enclosed switchgear (SF6 ring main unit) is a new generation of metal-enclosed switchgear that uses sulfur hexafluoride load switch as the main switch and the entire cabinet adopts air insulation. It is suitable for power distribution automation and is compact and expandable.

Product Overview

XGN2-12 box-type fixed metal-enclosed switchgear (hereinafter referred to as equipment) is suitable for 3.6~12kV three-phase AC 50Hz single bus or single bus with bypass power system. It is mainly used in power distribution places such as power plants, substations and industrial and mining enterprises to receive and distribute electric energy, and control, protect and monitor the circuit.

This product complies with relevant standards such as IEC60298, IEC62271-200, IEC62271-1, GB3906, GB/T11022, DL/T404, etc. The equipment can use a variety of fixed vacuum circuit breakers such as VS1-12, VD4-12, VEP-12, HVX12, EV12, VBG-12, 3AE-EP, VYG-12, eVB-12, ZN28A-12, etc. The isolating switch adopts GN30-12 (D) rotary isolating switch or GN22-12 high current isolating switch series products. Due to the selection of new electrical components, high technical performance and novel design, the cabinets are closed, the instrument room, busbar room, circuit breaker room and cable room in the cabinet are separated and closed, and each room has independent natural ventilation (except the instrument room). It has the characteristics of reasonable structure, high safety and reliability, simple operation, convenient inspection and maintenance, etc., which meets the "five-protection" locking function requirements.

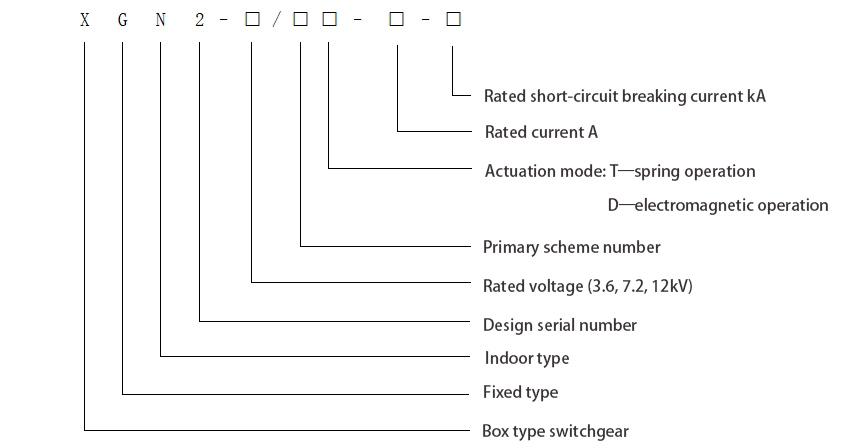

Product Model Meaning

Normal Use Environment Conditions

1. Ambient temperature: not higher than +40℃, not lower than -25℃, and the average temperature within 24 hours is not higher than +35℃. The equipment should be used at reduced capacity when the ambient temperature exceeds the above.

2. Relative humidity: daily average value is not more than 95%, and monthly average value is not more than 90%.

3. Altitude: the installation site shall not exceed 1000m. Above 1000m above sea level, the capacity shall be reduced accordingly.

4. Earthquake intensity: not more than 8 degrees.

5. The equipment should be installed in a place without fire, explosion hazard, severe vibration, chemical corrosion and other serious pollution.

6. If the above conditions of use cannot be met, the user and the manufacturer shall negotiate to resolve.

Main Technical Parameters

1. Equipment technical parameters

|

Serial number |

Project |

Unit |

Parameter |

||

|

1 |

Rated voltage |

kV |

3.6、7.2、12 |

||

|

2 |

Main bus rated current |

A |

630、1250、1600、2000、2500、3150、4000 |

||

|

3 |

Branch bus rated current |

A |

630、1250、1600、2000、2500、3150、4000 |

||

|

4 |

Rated frequency |

Hz |

50 |

||

|

5 |

Rated short-circuit breaking current (effective value) |

kA |

20、31.5、40 |

||

|

6 |

Rated short-circuit closing current (peak value) |

kA |

50、80、100 |

||

|

7 |

Rated peak withstand current |

kA |

50、80、100 |

||

|

8 |

Rated short-time withstand current/duration (effective value) |

kA/s |

20/4、31.5/4、40/4 |

||

|

9 |

Rated insulation level |

1min rated short-time power frequency withstand voltage (effective value) |

kV |

Phase to phase |

relative to ground |

|

42 |

48 |

||||

|

Rated lightning impulse withstand voltage (peak value) |

kV |

75 |

85 |

||

|

10 |

Auxiliary circuit rated voltage |

V |

AC/DC110、220 |

||

|

11 |

Auxiliary circuit 1min short-time power frequency withstand voltage |

V |

2000 |

||

|

12 |

Protection level Unit |

- |

IP3X |

||

|

13 |

Dimensions (width x depth x height) |

mm |

1100(1200)X1200X2650 |

||

|

14 |

Weight |

kg |

About 1000 |

||

Note:

* When the rated current is 1250A or less for overhead incoming and outgoing lines, the cabinet depth is 1600mm;

* When the rated current is 2000A or more for overhead incoming and outgoing lines, the cabinet depth is 1900mm;

* When the current is large (2000A or more), the cabinet width is 1200mm, and the disconnector can use GN22/GN30;

* The cabinet depth with bypass is 1900mm.

2. Technical parameters of ZN28A-12 vacuum circuit breaker

|

Serial number |

Project |

Unit |

Parameter |

|

|

1 |

Rated voltage |

kV |

12 |

|

|

2 |

Rated insulation level |

1min rated short-time power frequency withstand voltage (effective value) |

kV |

42 |

|

Rated lightning impulse withstand voltage (peak value) |

75 |

|||

|

3 |

Rated current |

A |

630、1250、1600、2000、2500、3150 |

|

|

4 |

Rated frequency |

Hz |

50 |

|

|

5 |

Rated short-circuit breaking current |

kA |

20、31.5、40 |

|

|

6 |

Rated short-circuit closing current (peak value) |

kA |

50、80、100 |

|

|

7 |

Rated short-time withstand current/duration (effective value) |

kA/s |

20/4、31.5/4、40/4 |

|

|

8 |

Rated peak withstand current (peak value) |

kA |

50、80、100 |

|

|

9 |

Rated short-circuit breaking current breaking times |

time |

30 |

|

|

10 |

Rated operation sequence |

|

O-0.3s-CO-180s-CO |

|

|

11 |

Mechanical life |

time |

10000 |

|

3. VS1 vacuum circuit breaker technical parameters

|

Serial number |

Project |

Unit |

Parameter |

|

|

1 |

Rated voltage |

kV |

12 |

|

|

2 |

Rated insulation level |

1min rated short-time power frequency withstand voltage (effective value) |

kV |

42 |

|

Rated lightning impulse withstand voltage (peak value) |

75 |

|||

|

3 |

Rated current |

A |

630、1250、1600、2000、2500、3150、4000 |

|

|

4 |

Rated frequency |

Hz |

50 |

|

|

5 |

Rated short-circuit current Breaking current |

kA |

20、25、31.5、40 |

|

|

6 |

Rated short-circuit closing current (peak value) |

kA |

50、63、80、100 |

|

|

7 |

Rated short-time withstand current/duration (effective value) |

kA/s |

20/4、25/4、31.5/4、40/4 |

|

|

8 |

Rated peak withstand current (peak value) |

kA |

50、63、80、100 |

|

|

9 |

Rated operation sequence |

|

O-0.3s-CO-180s-CO O-180s-CO-180s-CO(50kA) |

|

|

10 |

Closing time |

ms |

35~70 |

|

|

11 |

Opening time |

ms |

20~50 |

|

|

12 |

Mechanical life |

time |

20000(50kA for 10000time) |

|

|

13 |

Contact opening distance |

mm |

11±1 |

|

|

14 |

Overtravel |

mm |

3.5±1 |

|

|

15 |

Accumulated thickness of contact wear allowed |

mm |

3 |

|

|

16 |

Average closing speed |

ms |

0.5-0.8 |

|

|

17 |

Average opening speed (just 6mm) |

ms |

0.9-1.2 |

|

|

18 |

Contact closing bounce time |

ms |

≤2 |

|

|

19 |

Three-phase contact closing at different times |

ms |

≤2 |

|

|

20 |

Three-phase contact opening at different times |

ms |

≤2 |

|

|

21 |

DC resistance of each phase circuit |

μΩ |

≤60(630A) ≤50(1250A) ≤35(1600~2000A)≤25(2500A以上) |

|

4. Technical parameters of high current isolating switch

|

Serial number |

Project |

Unit |

GN22-12/2000-40 |

GN22-12/3150~ 4000-50 |

|

|

1 |

Rated voltage |

kV |

12 |

||

|

2 |

Rated insulation level |

1min rated short-time power frequency withstand voltage (effective value) |

kV |

42 |

|

|

Rated lightning impulse withstand voltage (peak value) |

48 |

||||

|

3 |

Rated current |

A |

2000 |

3150~4000 |

|

|

4 |

Rated frequency |

Hz |

50 |

||

|

5 |

Rated short-circuit breaking current |

kA |

40 |

50 |

|

|

6 |

Rated Rated short-circuit closing current (peak value) |

kA |

100 |

125 |

|

|

7 |

Rated short-time withstand current/duration (effective value) |

kA/s |

40/4、50/4 |

||

|

8 |

Rated peak withstand current (peak value) |

kA |

100、125 |

||

|

9 |

Distance between main circuit conductor (high potential) and ground |

mm |

Not less than 125 |

||

|

10 |

Three-phase just-closed position synchronization |

mm |

≤3 |

||

|

11 |

Three-phase just-closed position deviation |

mm |

≤2 |

||

5. Technical parameters of rotary isolating switch 1

|

Serial number |

Project |

Unit |

GN30-12/630-20 |

GN30-12/1000 -31.5 |

|

|

GN30-12D/630-20 |

GN30-12D/1000-31.5 |

||||

|

1 |

Rated voltage |

kV |

12 |

||

|

2 |

Rated insulation level |

1min rated short-time power frequency withstand voltage (effective value) |

kV |

42 |

|

|

Rated lightning impulse withstand voltage (peak value) |

48 |

||||

|

3 |

Rated current |

A |

630 |

1000 |

|

|

5 |

Rated short-time withstand current/duration (effective value) |

kA/s |

20/4、31.5/4 |

||

|

6 |

Rated peak withstand current (peak value) |

kA |

50、80 |

||

|

7 |

Distance between main circuit conductor (high potential) and ground |

mm |

Not less than 125 |

||

|

8 |

Spring positive pressure |

N |

400±40 |

600±60 |

|

|

9 |

Three-phase just-closed position synchronization |

mm |

≤3 |

||

|

10 |

Three-phase just-closed position deviation |

mm |

≤2 |

||

|

11 |

DC resistance of each phase circuit |

μΩ |

≤70 |

≤45 |

|

6. Technical parameters of rotary isolating switch 2

|

Serial number |

Project |

Unit |

GN30-12/1250-40 |

GN30-12/2000~ 4000-50 |

|

|

GN30-12D/1250-40 |

GN30-12D/2000~4000-50 |

||||

|

1 |

Rated voltage |

kV |

12 |

||

|

2 |

Rated insulation level |

1min rated short-time power frequency withstand voltage (effective value) |

kV |

42 |

|

|

Rated lightning impulse withstand voltage (peak value) |

48 |

||||

|

3 |

Rated current |

A |

1250 |

2000~4000 |

|

|

7 |

Rated short-time withstand current/duration (effective value) |

kA/s |

40/4、50/4 |

||

|

8 |

Rated peak withstand current (peak value) |

kA |

100、125 |

||

|

9 |

Distance between main circuit conductor (high potential) and ground |

mm |

Not less than 125 |

||

|

10 |

Spring positive pressure |

N |

600±60 |

||

|

11 |

Three-phase just-closed position synchronization |

mm |

≤3 |

||

|

12 |

Three-phase just-closed position deviation |

mm |

≤2 |

||

|

13 |

DC resistance of each phase circuit |

μΩ |

≤45 |

||

Structural Features

This equipment is a metal enclosed box structure. The shell is divided into 4 separate compartments. The shell protection level is IP3X, which can effectively prevent short-circuit faults caused by foreign objects entering the cabinet, and prevent the human body from approaching live parts and moving parts. There are functional schemes such as cable inlet and outlet, overhead inlet and outlet, communication, isolation, and metering. The equipment of each scheme can be arranged according to the purpose to form a distribution device that can complete the designed function.

1. The cabinet frame is welded by angle steel. The cabinet structure has high strength. The cabinet is divided into circuit breaker room, busbar room, cable room, and relay room by steel plates. The operation of the main components can be observed through the observation window and lighting on the door.

2. The main electrical components of the equipment have their own independent compartments, namely the circuit breaker room, busbar room, cable room, and relay instrument room. The busbar room is in the upper back of the cabinet, and the busbars are arranged in a product shape. Busbar bushings can be installed between cabinets to prevent the failure of one equipment from affecting adjacent equipment and prevent "fire burning" accidents.

3. To improve the technical performance of the product, the main components of this equipment are new electrical components. The air insulation distance between phases and relative to the ground is greater than 125mm, and no form of phase-to-phase or relative to the ground insulation partition (or composite insulation) is used. The cabinet uses a large creepage distance insulator support (or bushing) to make the switch cabinet meet the insulation requirements of all working conditions.

4. The circuit breaker room is at the bottom of the cabinet, and the circuit breaker is fixedly installed at a position close to the ground. There is a large maintenance space, and the maintenance personnel can easily stand in place to inspect and maintain the main switch. The circuit breaker room is also equipped with a pressure relief channel. If an internal arc occurs, the gas can release the pressure through this channel.

5. A rotary isolating switch is used. When the isolating switch is in the disconnecting position, the rotating conductor is grounded, that is, a "metal isolation" (that is, two ground interfaces) is formed between the charged body (such as the main busbar) and the isolated conductor (such as the circuit breaker). At this time, the charged body can only discharge between phases or relative to the ground, and will not affect the isolated conductor, thereby ensuring the safety of the maintenance personnel.

6. The cable room is at the lower rear of the cabinet. The supporting insulators in the cable room can be equipped with a monitoring device. A rubber sealing plate is used between the cable room and the cable trench to prevent moisture and small animals from entering the cabinet through the cable trench.

7. The switch cabinet is double-sided maintenance. The front side is used to inspect the secondary components of the relay room, maintain the operating mechanism, mechanism interlock and transmission part, and inspect the circuit breaker. The back side is used to repair the main bus and cable terminals. A lighting lamp is installed in the circuit breaker room.

8. Anti-misoperation interlocking device

The main switch, disconnector and cabinet door are forced to use a mechanical interlocking method. The interlocking (JSXGN-12) has a simple, reasonable structure and is easy to operate. It can reliably meet the requirements of "five protections". Its main features are:

8.1 Five protections are reliable

8.1.1 This interlocking can only pull the handle from the "working" position and turn it right to the "disconnection lock" position after the circuit breaker is actually disconnected, and the disconnector can be opened and closed, which prevents the disconnector from being opened and closed with load.

8.1.2 When the circuit breaker and the upper and lower isolating switches are in the closed state and the handle is in the "working" position, the front and rear cabinet doors cannot be opened to prevent accidental entry into the live interval.

8.1.3 When the circuit breaker and the upper and lower isolating switches are in the closed state, the handle cannot be turned to the "maintenance" or "disconnection lock" position. When the handle is in the "disconnection lock" position, only the upper and lower isolating switches can be closed and opened, and the circuit breaker cannot be closed, avoiding accidental closing of the circuit breaker.

8.1.4 When the upper and lower isolating switches are not opened, the grounding switch cannot be closed, and the handle cannot be rotated from the "disconnection lock" position to the "maintenance" position to prevent the grounding wire from being hung with power.

8.1.5 When the grounding switch is not opened, the upper and lower isolating switches cannot be closed to prevent the upper and lower isolating switches from being closed with the grounding wire.

8.2 Easy to operate

This interlock usually does not use program locks, and all programs are implemented by mandatory functions.

Note: The rear cabinet door is a cabinet door lock, and the front cabinet door wall is a knife lock. After the front cabinet door opens the knife lock, the front cabinet door cannot be closed. At this time, take out the program key to open the rear cabinet door for maintenance. Only after closing the rear cabinet door and taking out the key to close the front cabinet door knife lock, the front cabinet door can be closed (the key does not need to be taken out at this time), and then the program operation can be performed.

If the user needs, the program lock (electromagnetic lock) installation hole and auxiliary switch installation hole can be added to the interlock.

8.3 Convenient maintenance

Unless the rear cabinet door needs to be opened for maintenance of the cable or busbar room, the rest of the maintenance only needs to open the front cabinet door. During maintenance, just disconnect the isolating switch, close the grounding switch, turn the handle from the "disconnection lock" position to the "maintenance" position, open the front cabinet door, and you can perform maintenance and maintenance.

8.4 Simple structure

This interlock adopts mechanical transmission, requires fewer parts, is small in size, and is easy to install and use.

9. Live display device

The equipment can be equipped with a live display device to monitor the live status of the primary circuit. The device can not only indicate the live status of the high-voltage circuit, but also cooperate with the electromagnetic lock to realize the forced locking of the handle, door, etc., thereby improving the product's anti-error performance.

10. Measures to prevent condensation

In order to prevent the equipment from causing creepage and flashover accidents caused by condensation inside the equipment in a climate environment with high humidity or large temperature changes, which may cause harm to the equipment, heaters controlled by thermostats are installed in the circuit breaker room and cable room respectively, so as to use it in the above environment and prevent corrosion.

11. Grounding device

The equipment is equipped with a grounding busbar that runs through the entire equipment (the specifications are determined according to the system parameters), and it has good contact with the functional unit cabinet, which is used for directly grounded components, so that the entire equipment is in a good grounding state, and the indirect grounding busbar of the equipment is effectively connected to ensure the continuity of the system grounding and the safety of the operator.

Application Case

Warehouse Real Scene

Generate Workshop

Product Packaging

Hot Tags :

Can't Find Target Products? contact us!