What Are You Looking For?

What Are You Looking For?

⚡ Flexible combination schemes

⚡ Trolley block design for interchangeable components

⚡ Five-protection interlocking function

⚡ Safe pressure relief channel

⚡ Visual design with observation window

⚡ Distribution protection and monitoring

⚡ Circuit breaker and line protection

⚡ Temperature and humidity monitoring

Item NO. :

KYN28-12/24Lead time :

35 DaysPayment :

T/TMOQ :

≥1Warranty :

1 YearKYN28-12/24 Armored Removable AC Metal-enclosed Switchgear

Enecell is Armored Removable AC Metal-enclosed Switchgear Supplier, KYN28-12 armored removable AC metal-enclosed switchgear is mainly used in 3.6-12kV power systems, as a power distribution room for power plants, substations and industrial and mining enterprises to receive and distribute electric energy, with control, protection and monitoring functions.

The central removable component (hereinafter referred to as the trolley) structure is equipped with a high breaking capacity and low current cutoff value vacuum circuit breaker, with "five-protection" interlocking, meeting the requirements of IEC298, GB3906 and other technical standards, combined with digital comprehensive protection devices, to protect the safety of power transmission and distribution.

Product Overview

KYN28-12 armored removable AC metal-enclosed switchgear (hereinafter referred to as the equipment) is suitable for 3.6~12kV three-phase AC 50Hz single busbar and single busbar segmented power systems. It is mainly used in power plants, small and medium-sized generators, power distribution in industrial and mining enterprises and institutions, and power receiving and distribution of power in secondary substations of power systems and starting of large high-voltage motors to control, protect and detect circuits.

This product complies with the requirements of relevant standards such as IEC60298, IEC62271-200, IEC62271-1, GB3906, GB/T11022, DL/T404, and has perfect "five protection" functions. The equipment has strong applicability and can be configured with circuit breakers such as VS1-12, VD4-12, VEP-12, HVX12, EV12, VBG-12, 3AE-EP, VYG-12, eVB-12 and grounding switches such as JN15-12 and EK6 to meet the needs of different users.

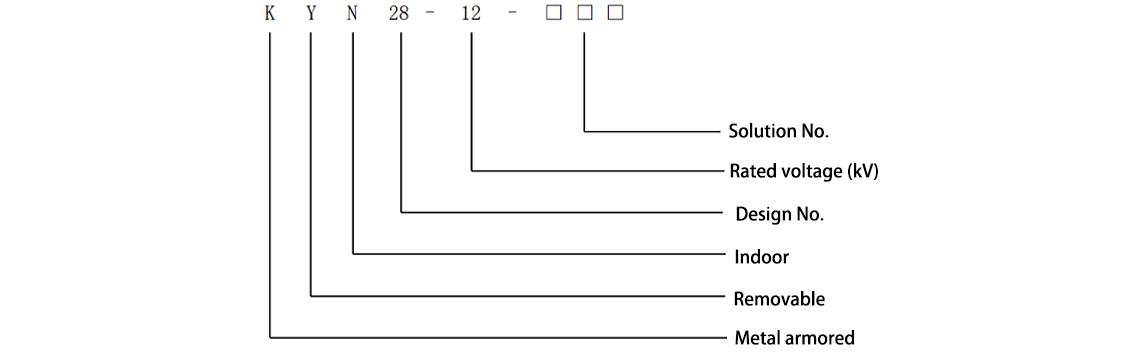

Product Model Meaning

Normal Use Environment Conditions

1. Ambient temperature: not higher than +40℃, not lower than -15℃, and the average temperature within 24 hours is not higher than +35℃. The equipment should be used at reduced capacity when the ambient temperature exceeds the above.

2. Relative humidity: daily average value is not more than 95%, and monthly average value is not more than 90%.

3. Altitude: the installation site shall not exceed 1000m. Above 1000m above sea level, the capacity shall be reduced accordingly.

4. Earthquake intensity: not more than 8 degrees.

5. The equipment should be installed in a place without fire, explosion hazard, severe vibration, chemical corrosion and other serious pollution.

6. If the above conditions of use cannot be met, the user and the manufacturer shall negotiate to resolve.

Main technical parameters

1. Equipment technical parameters

|

Serial number |

project |

unit |

Parameters |

||

|

1 |

Rated voltage |

kV |

3.6、7.2、12 |

||

|

2 |

Main bus rated current |

A |

630、1250、1600、2000、2500、3150、4000、5000 |

||

|

3 |

Branch bus rated current |

A |

630、1250、1600、2000、2500、3150、4000、5000 |

||

|

4 |

Rated frequency |

Hz |

50 |

||

|

5 |

Rated short-circuit breaking current (effective value) |

kA |

20、25、31.5、40、50 |

||

|

6 |

Rated short-circuit making current (peak value) |

kA |

50、63、80、100、125 |

||

|

7 |

Rated peak withstand current |

kA |

50、63、80、100、125 |

||

|

8 |

Rated short-time withstand current/duration (effective value) |

kA/s |

20/4、25/4、31.5/4、40/4、50/4 |

||

|

9 |

Rated insulation level |

1min rated short-time power frequency withstand voltage (effective value) |

kV |

Phase to phase, relative to ground |

Primary isolation break |

|

42 |

48 |

||||

|

Rated lightning impulse withstand voltage (Peak) |

kV |

75 |

85 |

||

|

10 |

Auxiliary circuit rated voltage |

V |

AC/DC110、220 |

||

|

11 |

Auxiliary circuit 1min short-time power frequency withstand voltage |

V |

2000 |

||

|

12 |

Protection level |

- |

Housing IP4X IP2X when the compartment and circuit breaker room doors are opened |

||

|

13 |

Overall dimensions (width x depth x height) |

mm |

650(800、1000)X1500(1660)X2300 |

||

|

14 |

weight |

kg |

About 700~1200 |

||

Note:

*The short-circuit capacity of the current transformer needs to be considered separately;

*Rated current of 4000A and above requires forced air cooling;

*When the rated current is above 1600A, the cabinet width is 1000mm;

*The equipment depth of the overhead line scheme behind the cabinet is 1660mm;

*When the circuit breaker is used to control 3~10kV motors, if the starting current is less than 600A, a metal zinc oxide lightning arrester must be added. The specific requirements are negotiated between the user and our company; when the circuit breaker is used to disconnect the capacitor bank, the rated current of the capacitor bank should not be greater than 80% of the rated current of the circuit breaker.

2. Technical parameters of VD4 vacuum circuit breaker

|

Serial number |

project |

unit |

Parameters |

|

|

1 |

Rated voltage |

kV |

12 |

|

|

2 |

Rated insulation level |

1min rated short-time power frequency withstand voltage (effective value) |

kV |

42 |

|

Rated lightning impulse withstand voltage (Peak) |

75 |

|||

|

3 |

Rated current |

A |

630、1250、1600、2000、2500、3150、4000 |

|

|

4 |

Rated frequency |

Hz |

50 |

|

|

5 |

Rated short-circuit breaking current |

kA |

25、31.5、40 |

|

|

6 |

Rated short-circuit making current (peak value) |

kA |

63、80、100 |

|

|

7 |

Rated short-time withstand current/duration (effective value) |

kA/s |

25/4、31.5/4、40/4 |

|

|

8 |

Rated peak withstand current (peak) |

kA |

63、80、100 |

|

|

9 |

Rated operating sequence |

|

O-0.3s-CO-15s-CO |

|

|

10 |

Closing time |

ms |

50~80 |

|

|

11 |

Opening time |

ms |

40~60 |

|

|

12 |

Mechanical life |

Second-rate |

30000 |

|

3. Technical parameters of EV12 vacuum circuit breaker

|

Serial number |

project |

unit |

Parameters |

|

|

1 |

Rated voltage |

kV |

12 |

|

|

2 |

Rated insulation level |

1min rated short-time power frequency withstand voltage (effective value) |

kV |

42 |

|

Rated lightning impulse withstand voltage (Peak) |

75 |

|||

|

3 |

Rated current |

A |

630、1250、1600、2000、2500、3150、4000 |

|

|

4 |

Rated frequency |

Hz |

50 |

|

|

5 |

Rated short-circuit breaking current |

kA |

25、31.5、40 |

|

|

6 |

Rated short-circuit making current (peak value) |

kA |

63、80、100 |

|

|

7 |

Rated short-time withstand current/duration (effective value) |

kA/s |

25/4、31.5/4、40/4 |

|

|

8 |

Rated peak withstand current (peak) |

kA |

63、80、100 |

|

|

9 |

Rated operating sequence |

|

O-0.3s-CO-180s-CO O-0.3s-CO-15s-CO |

|

|

10 |

Closing time |

ms |

≤68 |

|

|

11 |

Opening time |

ms |

≤45 |

|

|

12 |

Mechanical life |

Second-rate |

30000 |

|

|

13 |

Contact opening distance |

mm |

9±1 |

|

|

14 |

Contact closing bounce time |

ms |

≤2 |

|

|

15 |

Three-phase contacts close at different times |

ms |

≤2 |

|

|

16 |

Three-phase contact opening at different times |

ms |

≤2 |

|

4. VS1 vacuum circuit breaker technical parameters

|

Serial number |

project |

unit |

Parameters |

|

|

1 |

Rated voltage |

kV |

12 |

|

|

2 |

Rated insulation level |

1min rated short-time power frequency withstand voltage (effective value) |

kV |

42 |

|

Rated lightning impulse withstand voltage (Peak) |

75 |

|||

|

3 |

Rated current |

A |

630、1250、1600、2000、2500、3150、4000,5000 |

|

|

4 |

Rated frequency |

Hz |

50 |

|

|

5 |

Rated short-circuit breaking current |

kA |

20、25、31.5、40、50 |

|

|

6 |

Rated short-circuit making current (peak value) |

kA |

50、63、80、100、125 |

|

|

7 |

Rated short-time withstand current/duration (effective value) |

kA/s |

20/4、25/4、31.5/4、40/4、50/4 |

|

|

8 |

Rated peak withstand current (peak) |

kA |

50、63、80、100、125 |

|

|

9 |

Rated operating sequence |

|

O-0.3s-CO-180s-CO O-180s-CO-180s-CO(50kA) |

|

|

10 |

Closing time |

ms |

35~70 |

|

|

11 |

Opening time |

ms |

20~50 |

|

|

12 |

Mechanical life |

Second-rate |

20000 (50kA is 10000 times) |

|

|

13 |

Contact opening distance |

mm |

11±1 |

|

|

14 |

Overtravel |

mm |

3.5±1 |

|

|

15 |

Contact allowable wear accumulation thickness |

mm |

3 |

|

|

16 |

Average closing speed |

ms |

0.5-0.8 |

|

|

17 |

Average opening speed (just 6mm) |

ms |

0.9-1.2 |

|

|

18 |

Contact closing bounce time |

ms |

≤2 |

|

|

19 |

Three-phase contacts close at different times |

ms |

≤2 |

|

|

20 |

Three-phase contact opening at different times |

ms |

≤2 |

|

|

21 |

DC resistance of each phase circuit |

mΩ |

≤60(630A) ≤50(1250A) ≤35 (1600~2000A) ≤25 (above 2500A) |

|

5. Technical parameters of VEP vacuum circuit breaker

|

Serial number |

project |

unit |

Parameters |

|

|

1 |

Rated voltage |

kV |

12 |

|

|

2 |

Rated insulation level |

1min rated short-time power frequency withstand voltage (effective value) |

kV |

42 |

|

Rated lightning impulse withstand voltage (Peak) |

75 |

|||

|

3 |

Rated current |

A |

630、1250、1600、2000、2500、3150、4000 |

|

|

4 |

Rated frequency |

Hz |

50 |

|

|

5 |

Rated short-circuit breaking current |

kA |

20、25、31.5、40、50 |

|

|

6 |

Rated short-circuit making current (peak value) |

kA |

50、63、80、100、125 |

|

|

7 |

Rated short-time withstand current/duration (effective value) |

kA/s |

20/4、25/4、31.5/4、40/4、50/4 |

|

|

8 |

Rated peak withstand current (peak) |

kA |

50、63、80、100、125 |

|

|

9 |

Rated operating sequence |

|

O-0.3s-CO-180s-CO |

|

|

10 |

Mechanical life |

Second-rate |

30000/20000 (40kA or more) |

|

|

11 |

Rated single/back-to-back capacitor bank breaking current |

A |

630/400 |

|

6. Technical parameters of JN15-12 grounding switch

|

Serial number |

project |

Unit |

Parameters |

|

|

1 |

Rated voltage |

kV |

12 |

|

|

2 |

Rated insulation level |

1min rated short-time power frequency withstand voltage (effective value) |

kV |

42 |

|

Rated lightning impulse withstand voltage (Peak) |

75 |

|||

|

3 |

Rated short-time withstand current/duration (effective value) |

kA/s |

31.5/4 |

|

|

4 |

Rated peak withstand current (peak) |

kA |

80 |

|

|

5 |

Rated short-circuit making current (peak value) |

kA |

80 |

|

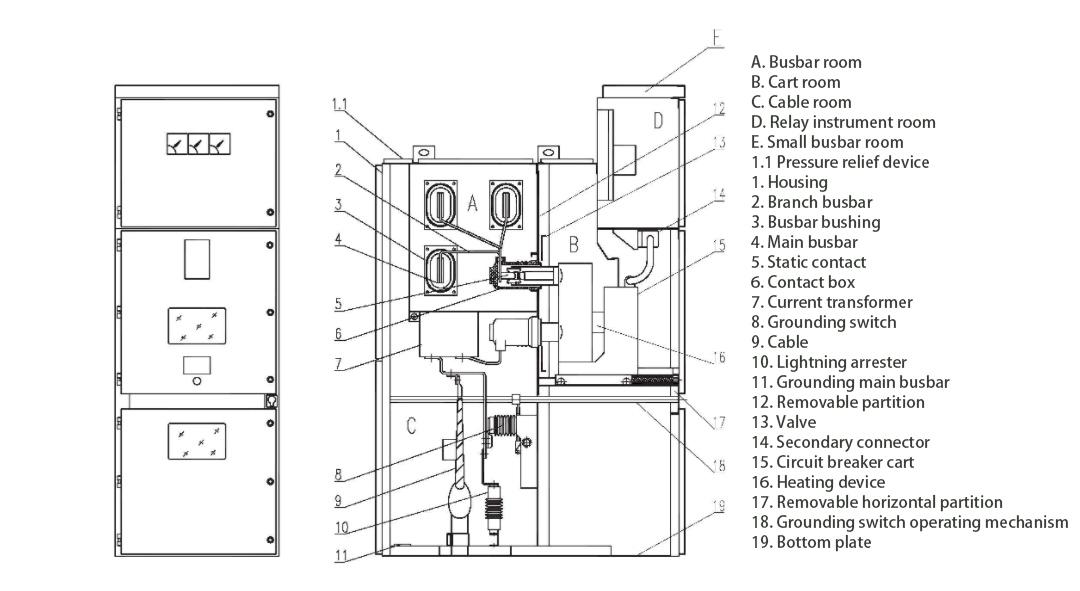

Structural features

This equipment is mainly composed of two parts: a cabinet and a central removable component (i.e., a trolley). The shell is divided into five separate compartments, and the protection level of the shell is IP4X. When the trolley compartment door is opened and the trolley is in the test position, the protection level is IP2X. There are functional schemes such as cable inlet and outlet, overhead inlet and outlet, communication, isolation, and metering. The equipment of each scheme can be arranged according to the purpose to form a distribution device that can complete the designed function. The equipment is usually a high-low cabinet type, and can also be made into an equal-height cabinet type according to needs.

1. Cabinet

The cabinet is made of high-quality aluminum-zinc steel plate material, processed by CNC machine tools, and adopts multiple folding processes. The entire cabinet not only has high precision, strong corrosion and oxidation resistance, but also adopts multiple folding processes, so that the overall weight of the cabinet is light, the mechanical strength is high, and the appearance is beautiful. The cabinet adopts an assembled structure, connected by rivet nuts and high-strength bolts, which makes the equipment processing and production cycle short, the parts are highly versatile, and the floor space is small, which is convenient for organizing production.

2. Trolley

The trolley frame is made of high-quality cold-rolled steel plate and assembled after being processed by CNC machine tools. The trolley is insulated with the cabinet body, and the mechanical interlock is safe, reliable and flexible. According to different uses, trolleys can be divided into circuit breaker trolleys, isolation trolleys, voltage transformer trolleys, metering trolleys, lightning arrester trolleys and fuse trolleys, etc. Various types of trolleys are changed in a building block style, and trolleys of the same specification are completely interchangeable.

The trolley is a central structure, the entire trolley is small in size, and it is extremely convenient for inspection and maintenance. When the trolley needs to be removed from the cabinet, it can be easily removed with a special transfer vehicle for various inspections and maintenance. The trolley has a disconnection/test position and a working position in the cabinet. Each position has a positioning device to ensure reliable interlocking, and must be operated according to the interlocking anti-misoperation procedure. All kinds of trolleys use worm gear and worm propulsion mechanisms to achieve advancement and withdrawal. The operation is light and flexible, suitable for various on-duty personnel.

The circuit breaker trolley is equipped with a vacuum circuit breaker and other auxiliary equipment. When the trolley is transported into the cabinet circuit breaker room by a transfer vehicle, it can be reliably locked in the disconnect/test position; and the cabinet position display can show its position. And only after it is completely locked, can the push mechanism be shaken to push the trolley to the working position. After the trolley reaches the working position, the push handle cannot be shaken, and its corresponding position display will show that it is in the working position. The mechanical interlock of the trolley can reliably ensure that the circuit breaker can only be closed when the trolley is in the working position or test position; and the trolley can only be moved when the circuit breaker is in the open state.

3. Compartments

The main electrical components of the equipment have their own independent compartments, namely the trolley room (also known as the circuit breaker room), busbar room, cable room, relay instrument room, and small busbar room. The protection level between each compartment reaches IP2X; except for the relay instrument room and the small busbar room, the other three compartments have their own independent pressure relief channels. Due to the adoption of the central structure, the space of the cable room is greatly increased, so the equipment can connect multiple cables.

3.1 Trolley room

Sliding tracks are installed on both sides of the trolley room for the trolley to move between the working position and the disconnection/test position. The static contact box partition (valve) is installed on the rear wall of the trolley room. When the trolley moves from the disconnection/test position to the working position, the valves on the upper and lower static contact boxes are linked with the trolley and automatically open at the same time; when the trolley is moved in the opposite direction, the valve automatically closes, completely covering the static contact box, forming an effective isolation, thereby ensuring that the operator does not touch the live body. When the door of the trolley room is closed, the trolley can also be operated. The position of the trolley, the display of the closing and opening switches, and the energy storage status can be observed through the observation window.

3.2 Busbar room

The main busbar is a single splicing and interconnected, fixed to the contact box through the branch busbar. The main busbar and the connecting busbar are copper bars with rectangular cross-sections; double busbars are used for large current loads. The branch busbar is connected to the contact box and the main busbar by bolts, and no other support is required. The busbars are insulated with heat shrink tubing and insulating sheaths. The busbars of adjacent equipment are fixed with sleeves. If an internal fault arc occurs in the cabinet, it can prevent the busbar from penetrating and melting, ensuring that the accident does not spread to the adjacent cabinet.

3.3 Cable room

The cable room can realize the upper and lower cable entry and exit scheme, and can also realize the overhead entry and exit scheme on the top of the equipment; when the cable entry and exit scheme is used, a specific cable connection conductor is provided in the cable room, and 1 to 3 cables can be connected in parallel for each phase, and up to 6 single-core cables can be connected in parallel. According to the needs of the main circuit scheme, the cable room can be installed with components such as current transformers, voltage transformers, grounding switches and lightning arresters. The bottom of the equipment is equipped with a removable cover plate to prevent eddy currents, which is convenient for cable construction.

3.4 Relay instrument room

The relay room is equipped with a mounting plate with mesh holes, which is convenient and quick to install or replace components. Various control components, protection components and other required secondary equipment can be installed; various comprehensive protection devices, instruments, intelligent control devices, operating switches, signal devices, etc. can be installed on the door of the relay room. A flip-type terminal board device is configured at the bottom of the relay room, which can realize comb-shaped neat wiring, reduce wiring space, and provide convenience for equipment wiring and maintenance.

3.5 Small busbar room

A small busbar room is set on the top of the relay room. Each equipment small busbar room is equipped with a set of small busbar terminals for fixing the small busbar. The small busbar is insulated with heat shrink tubing to ensure the safe and reliable operation of the small busbar. The small busbar room cover adopts a flip-type structure to facilitate the installation, wiring and maintenance of the small busbar on site.

4. Interlocking device to prevent misoperation

The equipment is equipped with a safe and reliable interlocking device, which fully meets the requirements of "five protections".

4.1 Preventing the circuit breaker from closing or opening by mistake

The instrument door is equipped with an operation button or control switch with an obvious prompt mark to prompt the next operation. When the circuit breaker trolley is pushed from the test position to the working position, the circuit breaker cannot be closed; after the circuit breaker is closed, the trolley's propulsion mechanism cannot be operated; after the circuit breaker is opened, the trolley is allowed to move between the test position and the working position, thereby preventing the circuit breaker from closing or opening by mistake.

4.2 Preventing the disconnection of the isolating contacts under load

The circuit breaker can only be opened and closed when the circuit breaker trolley is in the test position or the working position; the trolley can only be moved from the working position to the test position or pushed from the test position to the working position when the circuit breaker is in the open position, thereby effectively preventing the disconnection of the isolating contacts under load.

4.3 Preventing the earthing switch from closing with power on

When the earthing switch is in the open position, the circuit breaker trolley can be moved from the disconnected/test position to the working position; only when the circuit breaker trolley is in the disconnected/test position, the baffle of the earthing switch operating hole can be opened and the closing operation can be performed, which prevents the earthing switch from closing with power on and closing the circuit breaker when the earthing switch is in the closed position.

4.4 Preventing the earthing switch from entering the live compartment by mistake

The rear door of the equipment adopts mechanical or electrical interlocking mode. The rear door can only be opened when the earthing switch is closed and the rear door locking device of the earthing switch is unlocked. After the trolley is moved out of the cabinet, the valve outside the contact box of the trolley room is automatically closed to prevent touching the live parts in the contact box.

4.5 For circuit breakers, isolators, voltage transformers and other equipment without earthing switches, corresponding electromagnetic locks or program locks are configured to complete all the anti-mistake functions.

4.6 When the trolley is in the test position, the secondary aviation plug can be inserted or unplugged; when the trolley is in the working position, the secondary plug is locked.

5. Pressure relief device

Pressure relief devices are installed above the trolley room, busbar room and cable room. When an internal fault arc occurs in the circuit breaker or busbar, the air pressure inside the equipment increases with the arc. The special sealing ring installed on the door seals the front of the cabinet, and the pressure relief metal plate equipped on the top will automatically open to release pressure and discharge gas to ensure the safety of operators and equipment.

6. Live display device

The equipment can be equipped with a live display device to monitor the live state of the primary circuit. The device can not only indicate the live state of the high-voltage circuit, but also cooperate with the electromagnetic lock to realize the forced locking of the handle, door, etc., thereby improving the product's anti-error performance.

7. Prevent condensation and corrosion

In order to prevent the condensation inside the equipment from causing creepage and flashover accidents in a climate environment with high humidity or large temperature changes, which may cause harm to the equipment, heaters controlled by thermostats are installed in the trolley room and cable room respectively, so as to use them in the above environment and prevent corrosion.

8. Grounding device

The equipment trolley room and cable room are both equipped with reliable grounding devices. The cable room is equipped with a grounding busbar that runs through the entire equipment (the specifications are determined according to the system parameters), which is in good contact with the functional unit cabinet and is used for directly grounded components, so that the entire equipment is in a good grounding state, and the indirect grounding busbar of the equipment is effectively connected to ensure the continuity of the system grounding and the safety of the operator.

Ordering Instructions

When ordering, the user should provide the following information:

1. Main circuit diagram and primary system enclosure.

2. Auxiliary circuit electrical schematic diagram and terminal arrangement diagram. If there is no schematic diagram and terminal arrangement diagram, follow the manufacturer's standard.

3. Equipment arrangement and combination diagram and floor plan.

4. Model, specification and quantity of main electrical components in the equipment.

5. Inlet and outlet line mode and cable specifications. If busbar connection is required between equipment or incoming line units, busbar span, height from the ground and other data should be provided.

6. Surface color of the equipment.

7. Other special requirements should be negotiated with the manufacturer.

Application Case

Warehouse Real Scene

Generate Workshop

Product Packaging

Hot Tags :

Can't Find Target Products? contact us!