What Are You Looking For?

What Are You Looking For?

⚡ High technical performance

⚡ Compact design, maximizes functional units in smaller space

⚡ Modular design, users can choose to assemble them as needed

⚡ Enhanced safety with high-strength flame-retardant plastic components

⚡ Space-saving, efficient storage and transportation

⚡ Easy assembly, no complex tools required

Item NO. :

LMNSCertificate :

CQCLead time :

35 DaysPayment :

T/TMOQ :

≥1Warranty :

1 YearsLow Voltage Power Withdrawable Switchgear Cabinet LMNS

Enecell is MNS Low Voltage Withdrawable Switchgear Cabinet Manufacturer, Supplier, LMNS low-voltage withdrawable switchgear (hereinafter referred to as switchgear) is a fully assembled low-voltage switchgear with flexible structure, modularization, multi-function, reliable and safe performance. It is suitable for metallurgy, petroleum, chemical industry, industrial and mining enterprises and infrastructure fields, as a three-phase AC frequency of 50 (60) Hz, working rated voltage 380V (400) V, (690V), rated current below 6300A in the power distribution, control and other low-voltage systems in the power generation and power supply system.

LMNS low-voltage withdrawable switchgear has flexible structure, modularization, multi-function, reliable and safe performance. It is suitable for metallurgy, petroleum, chemical industry, industrial and mining enterprises and infrastructure, etc., as power distribution and motor centralized control equipment in three-phase AC power generation and supply systems.

LMNS combined assembly structure, the switch cabinet structure is composed of profiles (module E=25MM). Due to the use of locking self-tapping screws and 8.8-grade high-strength bolts, the cabinet has high precision and good stability, and the cabinet appearance and interior are separated.

Product Overview

LMNS is a product manufactured by our company using ABB technology. It is a combined low-voltage withdrawable complete set of equipment assembled with standard modules. It is suitable for power supply systems with AC 50-60Hz and rated working voltage of 660V and below. It is widely used in power plants, substations, industrial and mining enterprises and high-rise buildings for power receiving, feeding, reactive power compensation, electric energy metering, lighting and centralized control of motors.

This product complies with relevant standards such as IEC60439-1, GB7251 "Low-voltage complete switchgear and control equipment" and GB/T 24274 "Low-voltage withdrawable complete switchgear and control equipment".

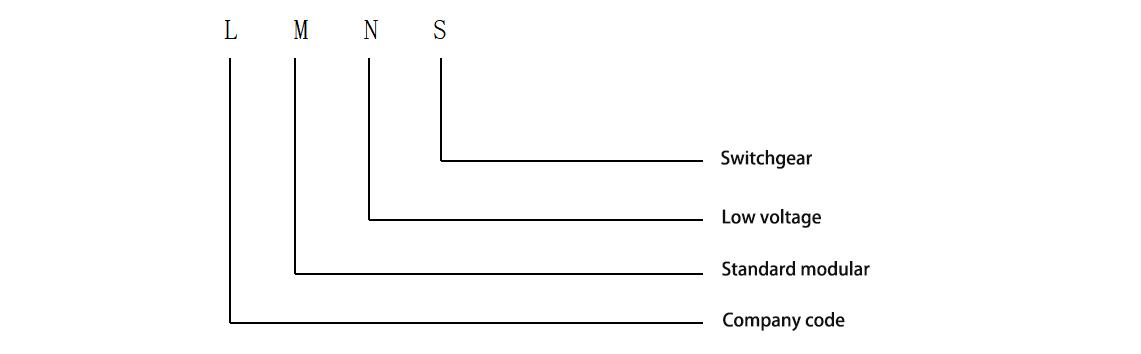

Product Model Meaning

Normal Use Environment Conditions

1. The ambient air temperature is not higher than +40℃, not lower than -5℃, and the average temperature within 24 hours is not higher than +35℃. The equipment should be used at reduced capacity when it exceeds the above environment.

2. The relative humidity does not exceed 50% when the maximum temperature is +40℃. A higher relative humidity is allowed at a lower temperature, such as 90% at +20℃. The influence of condensation that may occur accidentally due to temperature changes should be considered.

3. The installation site is usually installed at an altitude of no more than 2000m. Places above 2000m should be used at reduced capacity accordingly.

4. Install in a place without fire, explosion hazard, severe dust, chemical corrosion, severe vibration and impact.

5. If the above conditions cannot be met, the user and the manufacturer should negotiate to resolve.

Main Technical Parameters

|

Serial number |

project |

parameter |

|

|

1 |

Rated insulation voltage |

660V(1000V)/AC |

|

|

2 |

Rated operating voltage |

380V(660V)/AC |

|

|

3 |

Overvoltage level |

IV |

|

|

4 |

Pollution degree |

3 |

|

|

5 |

Rated frequency |

50(60)Hz |

|

|

6 |

Rated impulse withstand voltage |

8kV |

|

|

7 |

Main bus |

Rated current |

Up to 6300A |

|

Rated short-time withstand current |

Up to 100kA |

||

|

Rated peak withstand current |

Up to 220kA |

||

|

8 |

Vertical bus |

Rated current |

Up to 1200A |

|

Rated short-time withstand current |

Up to 50kA |

||

|

Rated peak withstand current |

Up to 110kA |

||

|

9 |

Protection level |

IP30 to IP54 |

|

|

10 |

Equipment height |

2200mm |

|

|

11 |

Device Width |

600,800,1000,1200mm |

|

|

12 |

Equipment Depth |

600,800,1000,1200mm |

|

Note: For the rear wiring solution, a cabinet depth of 1000mm is recommended.

Structural Features

This equipment is fully assembled and highly flexible. Its unique profile structure and connection method, as well as compatibility with various components, can meet the requirements of shorter construction period and power supply continuity. According to needs, the cabinet can be composed of drawer cabinets, fixed cabinets, mixed cabinets, fixed partition cabinets and other combinations.

1. Area division

According to different requirements, each device is divided into three compartments, namely, functional unit room, busbar room, and cable room. The compartments are separated from each other by steel plates or high-strength flame-retardant plastic functional boards to effectively prevent accidents caused by arcing caused by faults of switching components and short circuits between busbars.

1.1 The functional unit room is located in each independent compartment on the left side of the front of the cabinet, which is used to install drawer units or fixed partition units.

1.2 The busbar room is divided into the main busbar room and the distribution busbar room. The main busbar room is located behind the cabinet or on the top of the cabinet, and the distribution busbar room is located in an independent compartment on the left side of the rear of the cabinet.

1.3 The cable room is located on the right side of the front of the cabinet when the side outlet scheme is used, and on the right side of the rear of the cabinet when the rear outlet scheme is used.

2. Cabinet

2.1 The basic frame is composed of C-profiles. C-profiles are bent from steel plates or aluminum-zinc plates with E=25mm as the module mounting holes. They are connected by high-strength bolts and can be assembled into various forms of cabinets without special tools. They have high strength and flexibility. Cabinets of different specifications and uses can be assembled according to the corresponding modules according to different cabinet types or actual needs.

2.2 The structure is highly standardized, the parts are highly versatile, and the assembly is flexible. With E=25mm as the module, the structure and the withdrawable units can be arbitrarily combined to meet the needs of system design.

2.3 A variety of inlet and outlet line solutions are available (upper inlet and upper outlet, lower inlet and lower outlet, upper inlet and lower outlet, lower inlet and upper outlet).

2.4 According to the needs of system control, a small control busbar can be set up and installed in a dedicated compartment, which can be laid in the entire system.

2.5 The cable room is used for laying power cables and control cables. It is equipped with special primary and secondary wiring terminals and corresponding cable fixings (the primary and secondary wiring terminals of the rear outlet scheme can be laid out separately to avoid cross wiring). According to the cable specifications and the entry and exit methods, entry and exit holes are reserved on the bottom plate or top plate. The compartment design makes it very convenient for cables to enter and exit from top to bottom.

3. Busbar system

3.1 The main busbar can be arranged in an independent busbar room. Each phase consists of a single or multiple copper bars. It is installed on the top of the cabinet in the rear outlet scheme and on the rear or top of the cabinet in the side outlet scheme.

3.2 The distribution busbar is used to connect the functional unit and the main busbar. "L"-shaped or rectangular busbars can be selected and distributed in the vertical busbar channel. 3-phase or 4-phase distribution busbars can be installed as needed. They can be arranged in full height, half height or in two sections in the middle. After the drawer unit is pulled out, the protection level of the vertical busbar can reach IP20.

3.3 The neutral busbar and the main grounding busbar are installed in the cabinet and installed under the cabinet. The length of the busbar is determined by the transportation unit of the equipment. The neutral and grounding branch busbars are installed vertically in the cable room behind the cabinet or on the right side of the cabinet. They are equipped with standard modular holes for cable connection.

3.4 The busbars are all made of TMY-T2 series hard copper bars. The copper bar surface can be tinned, silvered and anti-oxidized as needed to improve the dynamic thermal stability of the busbar and the temperature rise of the contact surface.

4. Functional unit

4.1 Drawer-type functional unit

4.1.1 The design is compact, accommodating more functional units in a smaller space. The standard specifications of the drawer unit are 8E/4, 8E/2, 8E, 16E, and 24E. Each drawer cabinet has a maximum of 36 functional units. It has a complete mechanical interlocking device to ensure the safety of operation and maintenance.

|

Drawer unit type |

Height (mm) |

Width(mm) |

Maximum number of units per cabinet |

|

8E/4 |

200 |

150 |

36 |

|

8E/2 |

200 |

300 |

18 |

|

8E |

200 |

600 |

9 |

|

16E |

400 |

600 |

4 |

|

24E |

600 |

600 |

3 |

Drawer unit size

4.1.2 There are two types of drawer unit operating mechanisms, which can be selected according to needs.

A: New single-handle operating mechanism, that is, the interlocking handle (hereinafter referred to as the small handle) and the switch closing handle (hereinafter referred to as the large handle) are combined into one.

B: Double-handle operating mechanism, that is, the interlocking handle (hereinafter referred to as the small handle) and the switch opening and closing handle (hereinafter referred to as the large handle) are separated and operated independently.

4.1.3 The drawer unit has a total of 5 positions: closing position, opening position, test position, withdrawal/insertion position, and isolation position. The drawer unit can be accurately positioned by the operating handle. Each position has a corresponding mark, which is simple and intuitive. The operating handle can be equipped with a padlock to lock it in the corresponding position to avoid misoperation.

4.1.4 Each drawer unit is completely independent and the drawers are completely isolated. When the drawer unit is pulled out, the main power supply of the equipment does not need to be cut off. The drawer can be inserted/pulled out without powering off the adjacent drawer unit, and there will be no risk of electric shock.

4.1.5 The operating handle has electrical and mechanical interlocking functions. When the circuit breaker is closed, the corresponding mechanical interlocking device completes the drawer unit withdrawal lock to ensure the safety of operation. The electrical interlock is completed by a micro switch with one normally open contact and one normally closed contact.

4.1.6 During operation, it is possible to set parameters or check the internal conditions of the drawer unit. When the drawer panel needs to be opened, the front panel of the drawer unit can be opened with the corresponding tools.

4.1.7 The same drawer unit is fully interchangeable. The drawer unit plug capacity configuration is detailed in the table below (it is recommended to use the drawer unit structure when the rated current is 400A or less)

|

Drawer unit type |

8E/4 |

8E/2 |

8E |

16E |

24E |

|

Rated current |

45A |

63A |

250A |

400A |

630A |

4.1.8 The drawer unit is equipped with an instrument panel for installing metering, measuring, operating, indicating and other devices

A: The operation of the main switch of the 8E/4 and 8E/2 drawer units is achieved by a handle installed on the instrument panel.

B: The instrument panel of the 8E and above drawer units remains in place when the front panel is opened and closed, and the instrument panel of the single-handle operating mechanism has more sufficient installation space.

4.1.9 The primary outlet side is directly connected to the fixed outlet adapter, and the secondary outlet side is connected through a dedicated secondary connector. The number of secondary connectors of the 8E/4 drawer unit is up to 16 cores, and the number of secondary connectors of the 8E/2 and above drawer units is up to 32 cores.

4.1.10 The drawer unit adopts corresponding guide rails to guide the entry and exit and positioning of the drawer unit. The guide rails are equipped with anti-drop devices to effectively prevent the drawer from sliding when pulling the drawer unit.

4.2 Fixed-separation functional unit (based on fixed, plug-in, and withdrawable components)

4.2.1 This functional unit retains the advantages of simple structure and convenient operation of the fixed unit, and has the characteristics of clear separation and reliable isolation of the drawer-type functional unit, which is particularly suitable for high-current PC unit applications.

4.2.2 When the plug-in or withdrawable components are withdrawn for maintenance or replacement, there is no need to cut off the power supply. The use of such components can ensure that when the equipment is maintained, only the components of the corresponding circuit need to be withdrawn without affecting other circuits of the entire distribution system.

4.2.3 The functional unit is interlocked with the rotary handle on the panel through the operating mechanism, which can ensure that the panel of the functional unit can only be opened when the circuit breaker is in the open state, thereby enhancing the safety of equipment operation.

4.2.4 When the equipment is running, if you need to set or check the parameters of the internal components of the unit, you can use the corresponding unlocking tool to open the front panel.

Ordering Instructions

When ordering, users should provide the following information:

1. Schematic diagram of Feng circuit, primary system diagram.

2. Auxiliary circuit electrical schematic diagram, terminal arrangement diagram. If there is no schematic diagram and terminal arrangement diagram, follow the manufacturer's standards.

3. Equipment layout combination diagram, plane layout diagram.

4. Model, specification, and quantity of main electrical components in the equipment.

5. Inlet and outlet line mode, cable specifications. If busbar connection is required between equipment rooms or incoming line units, data such as busbar span and height from the ground should be provided.

6. Equipment surface color.

7. Other special requirements should be negotiated with the manufacturer.

Warehouse Real Scene

Generate Workshop

Product Packaging

Hot Tags :

Can't Find Target Products? contact us!