What Are You Looking For?

What Are You Looking For?

High degree of automation: intelligent design, protection system adopts microcomputer integrated automation device, decentralized installation, remote measurement, remote signaling, remote control, remote adjustment, namely "four remote".

Factory prefabrication: according to the main wiring diagram and the design of the equipment outside the box, determine the model and specifications of the main equipment components, install and debug in the complete set factory, and use directly on site. The high-voltage line can be directly sent to the load center.

Advanced, safe and reliable: the box body is made with advanced technology, the shell inter layer uses fireproof and heat-insulating materials, air conditioners and dehumidification devices are installed in the box body, and the operation of internal equipment is not affected by the outside world.

Low construction cost: compared with conventional substations of the same scale, the cost is reduced by 40%~50%, the floor area is only 1/10 of the substation of the same scale, and the appearance is beautiful and coordinated with the environment.

Item NO. :

YBM-12/0.4Lead time :

35 DaysPayment :

T/TMOQ :

≥1Warranty :

1 Year

YBM-12/0.4 Prefabricated Substation

Enecell is Intelligent Type Box Transformer Substation Manufacturer and Landscape Type Box Substation Supplier, YBM prefabricated substation is a compact complete set of distribution equipment that pre-assembles high-voltage distribution equipment with a rated voltage of 12kV, 12/0.4kV power transformer, low-voltage distribution equipment and electric energy metering equipment in one box.

YBM-12/0.4 prefabricated substation is suitable for 40.5~10kV power system, the distribution lines on both sides of the road in the urban network, residential areas, streets, large construction sites, high-rise buildings, industrial and mining enterprises and temporary facilities, etc., as power and lighting power supply.

YBM Package Transformer Substation is mainly used in power systems with a three-phase AC rated frequency of 50Hz and a rated voltage of 7.2~12/0.4kV for power and lighting power supply; it is suitable for the transformation of distribution lines on both sides of roads in the domain network, as well as in residential areas, streets, large construction sites, high-rise buildings, industrial and mining enterprises and temporary facilities.

Product Overview

ZNYBW series intelligent box-type substation is suitable for power supply systems with AC 50Hz, rated working voltage 12/0.4kV or 7.2/0.4kV, and rated capacity of 1250kVA and below. This product is composed of high-voltage distribution devices, transformers and low-voltage distribution devices, and is divided into three functional compartments, namely high-voltage room, transformer room and low-voltage room. The high-voltage and low-voltage rooms are fully functional. The primary power supply system of the high-voltage room can be arranged into a variety of power supply modes such as ring network power supply, terminal power supply, and dual power supply. High-voltage metering components can be installed to meet the requirements of high-voltage metering. The transformer room can choose low-loss, oil-immersed or dry-type transformers. The transformer room is equipped with a self-starting forced air cooling system and a lighting system. The low-voltage room can realize power distribution, lighting distribution, reactive power compensation and electric energy metering and other functions to meet the diverse needs of users.

Preinstalled Type Transformer Substation has many advantages, such as small footprint, simple installation, reliable operation, low investment, convenient maintenance, beautiful appearance, and can be coordinated with the surrounding environment. It can directly penetrate the load center and achieve the purpose of power transmission after one installation. Therefore, it is suitable for urban high-rise buildings, residential areas, tourist attractions, highways, airports and docks, railways, township and village power grids and other places.

This product complies with IEC1330 standards, GB17467-1998 "High/Low Voltage Prefabricated Substation" and other relevant standards.

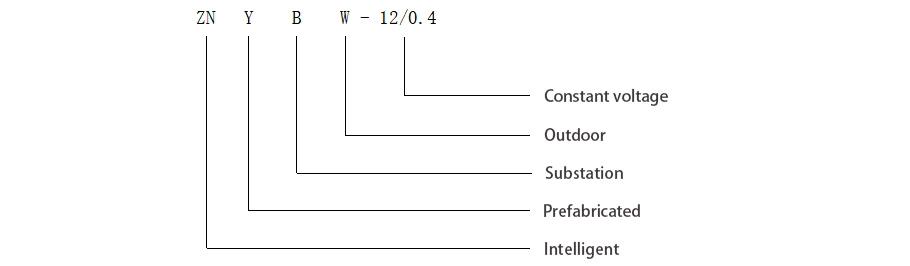

Product Model Meaning

Normal use environment conditions

1. The ambient air temperature is not higher than +40℃, not lower than -45℃, and its average temperature within 24 hours is not higher than +35℃. The equipment should be used at reduced capacity when it exceeds the above environment.

2. The relative humidity does not exceed 50% when the maximum temperature is +40℃. A higher relative humidity is allowed at a lower temperature, such as 90% at +20℃. The impact of condensation that may occur accidentally due to temperature changes should be considered.

3. The altitude does not exceed 1000m. If it is higher than 1000m, it should be used at reduced capacity accordingly.

4. Install in places without fire, explosion hazard, severe dust, chemical corrosion, severe vibration and impact.

5. If the above conditions cannot be met, the user and the manufacturer should negotiate to resolve.

Main technical parameters

| Project | Content | Unit | Parameter | |

| High Voltage Unit | Rated Voltage | kV | 12(7.2) | |

| Rated Frequency | Hz | 50 | ||

| Main Busbar Rated Current | A | 630 | Fuse rated current 125, 200 | |

| 1min Rated Short-time Power Frequency Withstand Voltage (To Earth and Between Phases/Isolated Interruption) | kV | 42/48 | ||

| Rated Lightning Impulse Withstand Voltage | kV | 75/85 | ||

| To Earth and Between Phases/Isolated Interruption | ||||

| Fuse Rated Short Circuit Breaking Current | kA | 31.5、40、50 | ||

| Rated Short Circuit Making Current (Peak Value) | kA | 50 | ||

| Rated Peak Withstand Current | kA | 50 | ||

| Rated Short-time Withstand Current / Duration | kA/s | 2024/2/20 | ||

| (Effective Value) | ||||

| Rated Transfer Current | A | 1500、1700、2000、3150 | ||

| Low Voltage Unit | Rated Operating Voltage | V | 400(660) | |

| Main Circuit Rated Current | A | Determined by user capacity | ||

| Rated Short-time Withstand Current / Duration | kA/s | 15、30、50、65/1 | ||

| (Effective Value) | ||||

| Rated Transfer Current | kA | 35、70、125、150 | ||

| Rated impulse withstand voltage | kV | 8 | ||

| Branch current | A | Determined by user capacity | ||

| Compensation capacity | kVar | Determined by user capacity | ||

| Transformer Unit | Rated capacity | kVA | 50~1250 | |

| Impedance voltage | % | 4.0、4.5 | ||

| Tap range | ±2×2.5% 、±5% | |||

| Connection group | Y,yn0、D,yn11 | |||

| Enclosure | Enclosure protection grade | IP33 | ||

| Sound level | dB | Oil immersion <55, dry type <65 | ||

| Dimensions | Determine different dimensions according to the plan | |||

Structural features

The 12kV intelligent box-type substation is mainly composed of a high-voltage room, a transformer room, and a low-voltage room, and is arranged in a "目" or "品" shape. The entire box adopts a modular design, and the modules are connected by bolts (no welding), which is convenient for the assembly of the box and the replacement of damaged parts.

1. Box

According to different use environments and conditions, different structural forms and materials can be selected for the box to meet different use requirements and ensure the normal operation of the substation. This series of substations can be divided into landscape box-type substations made of non-metallic materials, environmentally friendly box-type substations with sandwich color steel plates, and metal box-type substations made of high-quality steel plates. The basic structural features are as follows:

1.1 Landscape box-type substation

1.1.1 The box is made of glass fiber cement, which has strong bending resistance, impact resistance, tensile resistance, and weathering resistance, and can be maintenance-free for thirty years.

1.1.2 It has good moisture-proof performance and will not produce condensation due to changes in temperature.

1.1.3 It has good anti-exposure, anti-radiation and heat insulation functions.

1.1.4 It has good flame retardant performance and fireproof performance. Each room is isolated by high-quality steel plates to prevent further expansion after the accident.

1.1.5 The shape and color can be selected according to the surrounding environment, and it also plays a role in beautifying the environment.

1.2 Environmentally friendly box transformer

1.2.1 The box body is assembled with sandwich colored zinc steel plates, which has the characteristics of heat insulation, lightness, and corrosion resistance, and can be maintenance-free for 30 years.

1.2.2 The structure is flexible, which can maximize the use of space, save floor space, and adapt to the installation environment.

1.2.3 Each room is isolated with high-quality steel plates to prevent further expansion after the accident.

1.2.4 The unique roof design scheme enables it to have good ventilation while having heat insulation, heat preservation and anti-condensation dripping performance. The roof is cleverly connected to the main structure, which can not only ensure the sealing of the box body, but also facilitate and quickly disassemble it, which is convenient for the placement and replacement of transformers and high and low voltage switchgear from top to bottom.

1.2.5 The product is light, reliable and highly mobile.

2. High-voltage room

The high-voltage room of the box transformer is generally composed of high-voltage load switches, high-voltage fuses, current transformers, voltage transformers and lightning arresters, etc., which can be used for power outage operations and have overload and short-circuit protection.

The medium and high-voltage distribution devices of the box transformer can be divided into terminal type and ring network type according to the incoming line mode. If it is terminal wiring, a load switch-fuse combination appliance is used; if it is ring network wiring, a ring network cabinet power supply unit is used.

The high-voltage distribution device is a metal-enclosed box structure with an enclosure protection level of IP3X, which can effectively prevent short-circuit faults caused by foreign objects entering the cabinet and prevent the human body from approaching live objects and moving parts. There are functional schemes such as cable inlet and outlet, metering, voltage transformers, and lightning arresters. The equipment of each scheme can be arranged according to the purpose to form a distribution device that can complete the designed function.

2.1. The cabinet frame is assembled and spliced by KS (8MF) profiles, and the cabinet structure has high strength. The top of the equipment is the busbar room, and the front of the busbar room is the instrument room, which is separated by steel plates or insulating plates. The upper part of the cabinet is the load switch, the middle and lower parts are the cable outlets and other electrical components, and the operation of the main components can be observed through the observation window and lighting on the door.

2.2, Instrument room

Voltmeters, ammeters, transfer switches, relays, indicator lights and operating components can be installed in the instrument room, and the terminal blocks and protective fuses of the secondary circuit can be installed on the terminal board at the bottom of the instrument room. The instrument room of the metering cabinet can be equipped with active energy meters, reactive energy meters, peak and valley meters, etc.

2.3, Anti-misoperation interlocking device

The equipment has the following interlocks:

a. After the grounding switch is closed, the load switch cannot be operated;

b. After the load switch is closed, the grounding switch cannot be operated;

c. Only when the load switch is open and the grounding switch is closed, the front door of the equipment is allowed to be opened. In other cases, the door is in an interlocked state.

d. After the front door is opened, the load switch cannot be closed.

2.4. Live display device

The equipment can be equipped with a live display device to monitor the live status of the primary circuit. The device can not only indicate the live status of the high-voltage circuit, but also cooperate with the electromagnetic lock to realize the forced locking of the handle, door, etc., thereby improving the product's anti-error performance.

2.5. Measures to prevent condensation

In order to prevent the equipment from causing creepage and flashover accidents caused by condensation inside the equipment in a climate environment with high humidity or large temperature changes, which will cause harm to the equipment, a heater controlled by a thermostat is installed in the cabinet to use it in the above environment and prevent corrosion.

2.6. Grounding device

The equipment is equipped with a grounding busbar that runs through the entire equipment (the specifications are determined according to the system parameters), and it has good contact with the functional unit cabinet, which is used for directly grounded components, so that the entire equipment is in a good grounding state, and the indirect ground busbar of the equipment is effectively connected to ensure the continuity of the system grounding and the safety of the operator.

3. Transformer room

The transformer room is mainly composed of: transformer, automatic temperature control system, lighting and safety protection net, etc.

Ventilation holes are punched on the bottom plate of the box transformer, and cold air enters the box from the bottom of the box transformer. The door panels are all shutter doors with dustproof nets. This door has rainproof function and reliable ventilation, and can prevent dust from entering the box transformer. The top cover is punched with air cooling holes. After the cold air enters the box, natural ventilation is formed inside the box, and the hot air is discharged from the ventilation holes on the top cover. In order to increase the ventilation volume of the transformer, an axial flow fan is installed in the transformer room. It is controlled by a temperature controller. When the temperature of the transformer room is higher than the set temperature, the axial flow fan is automatically started to exhaust and cool down.

The transformer room is equipped with an isolation net door, and it is clearly marked on the door panel of the transformer room to avoid entering the interval by mistake.

The transformer can be installed on the transformer trolley, and a track is set on the bottom plate of the transformer room. The transformer can be dragged out for easy maintenance.

4. Low-voltage room

The power distribution cabinet in the low-voltage room is usually composed of GGD type low-voltage cabinets, which are equipped with low-voltage switches, electric meters, current transformers and other electrical components. On both sides of the low-voltage cabinet, the end partition structure is adopted to improve the protection capability. The electrical installation in the low-voltage room, the busbar arrangement is marked with obvious phase sequence marks; the electrical clearance and creepage distance of each component meet the national standards.

The GGD cabinet adopts a universal cabinet assembly structure. Because of its flexible and convenient assembly, the parts are designed according to the modularization, the universal coefficient is high, and pre-production can be realized, which not only shortens the production cycle, but also improves production efficiency. The equipment is designed for operation before and after the cabinet, wiring after the cabinet, and maintenance before and after the cabinet.

4.1 Selection of components in the cabinet

4.1.1 The equipment has good installation flexibility. The mainstream electrical components at home and abroad can be easily installed in the cabinet. At the same time, according to the principles of economy and rationality, some available old products are retained on the premise of fully considering feasibility.

4.1.2 Equipped with HD13BX and HS13BX isolating switches, it is easy to operate, labor-saving, and can ensure the safety of maintenance. At the same time, it is fully compatible with the installation of isolating switches (fuse-type isolating switches) such as QA, QP, QSA, GL, and GLR.

4.2 Cabinet

4.2.1 The cabinet frame is usually assembled by partial welding of 8MF cold-bent steel, and can also be assembled by C-profiles. The profiles are equipped with mounting holes with a modulus of 20mm, connected by high-strength bolts, and can be assembled into various forms of cabinets without special tools. It has high strength and flexibility.

4.2.2 The cabinet design fully considers the heat dissipation problem during the operation of the cabinet. There are different numbers of heat dissipation slots at the upper and lower ends of the cabinet. When the electrical components in the cabinet heat up, the heat rises and is discharged through the upper slots, and the cold air is continuously replenished into the cabinet from the lower slots, so that the sealed cabinet forms a natural ventilation duct from bottom to top to achieve the purpose of heat dissipation.

4.2.3 The cabinet body is designed in accordance with the requirements of modern industrial product design, and the golden ratio method is used to design the cabinet body shape and the division size of each part, making the whole cabinet beautiful and elegant, with a brand new look.

4.2.4 The cabinet door is connected to the frame with a rotating shaft hinge, which is easy to install and disassemble. A mountain-shaped rubber-plastic strip is embedded in the folding edge of the door. When closing the door, the strip between the door and the frame has a certain compression stroke, which can prevent the door from directly colliding with the cabinet body, and at the same time improve the protection level of the cabinet body.

4.2.5 The instrument door with electrical components is connected to the frame with multiple strands of soft copper wire. The mounting parts in the cabinet are connected to the frame with knurled screws, so that the whole cabinet constitutes a complete grounding protection circuit.

4.2.6 The cabinet surface adopts high-voltage electrostatic spraying technology, which has strong adhesion and good texture. The whole cabinet is matte, avoiding the glare effect and creating a more comfortable visual environment for the staff on duty.

4.2.7 The top cover of the cabinet can be removed when necessary to facilitate the assembly and adjustment of the main busbar on site. The four corners of the cabinet top are equipped with lifting rings for lifting and shipping.

4.2.8 The protection level of the cabinet is IP30, and it can be selected between IP20 and IP40 according to the user's installation site requirements.

4.3 Busbar system

4.3.1 The main busbar is installed horizontally on the top of the cabinet. Each phase is composed of a single or multiple rectangular copper bars, supported by a high-strength busbar frame, and has good dynamic stability.

4.3.2 The cabinet is equipped with a neutral busbar and a main grounding busbar, which are installed under the cabinet. The length of the busbar is determined according to the transportation unit of the equipment. Standard modular mounting holes are provided for the connection of incoming and outgoing cables.

4.3.3 The busbars are all made of TMY-T2 series hard copper bars. The surface of the copper bar can be tinned, silvered and anti-oxidized as needed to improve the dynamic thermal stability of the busbar and improve the temperature rise of the contact surface.

Application Case

Warehouse Real Scene

Generate Workshop

Product Packaging

Hot Tags :

Can't Find Target Products? contact us!